How To Cut Tempered Glass

You can cut ordinary glass (also called annealed glass) by scoring it with a glass cutter and snapping the glass along the score. You can cut glass mirrors the same way. Glass tiles, which are also ordinary glass, can be cut by scoring with a glass cutter or with a tile saw fitted with a glass cutting blade.

But tempered glass is not ordinary. And there is really no way to cut it—at least not without ruining its tempered quality.

What Is Tempered Glass?

Tempered glass is glass that has been cut to its final shape and size, heat treated in an 1,148-degree Fahrenheit oven and then quenched using a high-pressure cooling procedure. Quenching cools the outer surfaces of the glass faster than the center and as a result, the glass forms a tension between its surface and its center. That tension is what makes tempered glass about four times as strong as ordinary glass. That strength is stable as long as the structure of the glass panel is not disrupted, but any attempt to alter the panel after it has been tempered can disturb the balance of that dynamic tension, thereby causing the glass to shatter.

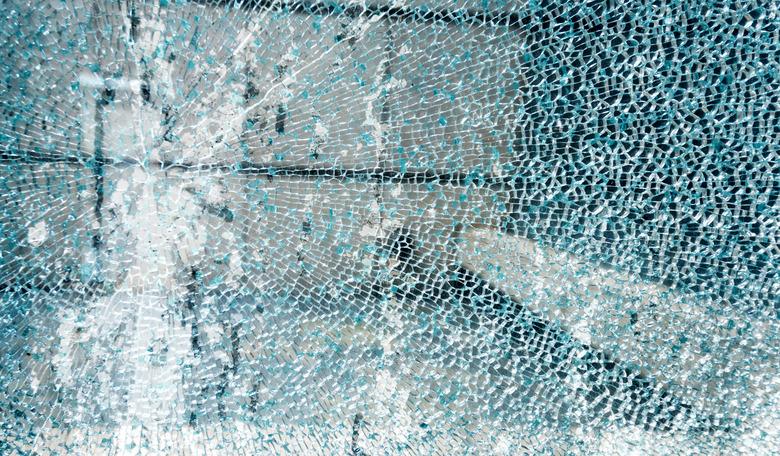

Tempered glass, when it shatters, breaks into small, pebbly, relatively harmless fragments. For that reason, almost all glass used architecturally in public places is required by code to be tempered "safety" glass. You also find tempered glass in residential settings for shower doors, patio tables, skylights and oven windows. Tempered glass panels are always cut and shaped before they are tempered; professional services may be able to grind down an edge slightly—no more than about 1/8 inch—but otherwise, the size of a piece of tempered glass is unalterable.

Misleading Instructions

You can find instructions online that purport to tell you how to cut tempered glass. Invariably, the process these sites describe begins with placing the glass panel into a kiln or craft oven capable of heating the glass to at least 900 degrees Fahrenheit, followed by a careful cooling process. In other words, you would be removing the temper and returning the panel to ordinary glass. At that point, you could cut it, but the glass would no longer have the desirable properties of tempered glass. If, as the outcome of this complicated procedure, you are going to be left with a piece of ordinary annealed glass, why not just start with a piece of ordinary glass in the first place?