7 Concrete Repair Products You Should Know About

Every building material has its primary weakness. Wood rots, metal corrodes, and concrete cracks. Concrete also is prone to surface damage, such as flaking or chipping. On the upside, concrete is so massive and durable that sound structures with cracks and surface damage can usually be repaired to like-new condition, unlike rotted wood and corroded metal. The secret to a successful concrete repair is using the right repair product. There are different repair materials for small vs. large cracks; horizontal vs. vertical structures; shallow vs. deep holes; and localized vs. widespread damage.

1. Concrete Crack Sealant

Concrete crack sealant is designed for cracks up to 1/2 inch wide in horizontal concrete surfaces. It is ideal for long, skinny cracks in driveways, garage floors, patios and walkways. The sealant is a concrete-colored, latex-based liquid that easily flows into cracks and is self-leveling so you don't have to smooth it with your finger or a putty knife to make it flush with the surrounding surface. It comes in a bottle that you shake before application, and you pour the sealant directly from the bottle's pointed tip into the crack. This makes it easier and less messy to apply than repair caulk.

Crack sealant can be applied in multiple layers to build up the repair. If the crack is deep, you can fill it partially full with sand before adding the sealant to the top 1/4 inch or so.

2. Concrete Repair Caulk

Concrete repair caulk comes in a tube and is applied just like regular latex or silicone caulk, using a standard caulk gun. Like concrete crack sealant, repair caulk is color-matched to concrete and can seal cracks up to 1/2 inch wide. But unlike sealant, caulk is suitable for vertical surfaces as well as horizontal. Repair caulk is latex-based and is mixed with sand to help it blend with the concrete when it dries. It can be applied in multiple layers, allowing it to dry between layers (something you shouldn't do with regular caulk).

3. Quick-Setting Cement

Cracks that are wider than 1/2 inch require a cement-based product rather than latex-based liquid sealant or caulk. Quick-setting cement mixes with water to create a stiff, clay-like putty that you force into cracks with a putty knife or trowel. If the crack is smaller than 1 x 1 inch, you may need to mix the cement with an acrylic fortifier to aid application and bonding. Fortifier also helps slow the cement's curing time for a stronger repair.

Quick-setting cement is also the best repair material for reshaping or rebuilding chipped or broken edges of concrete structures, like steps, curbs and slabs. On corners and vertical surfaces, you can use a board as a form to hold the cement in place until it sets enough to be sculpted or shaped as desired.

4. Hydraulic Cement

Hydraulic cement is also called water-stop cement, and the name indicates what it's used for. It's a very fast-setting cement repair material that is capable of plugging cracks and holes in concrete structures even while water is flowing out of the hole. Hydraulic cement comes in a dry powder that you mix with water into a pliable but firm dough. Then, you simply press the dough into the crack or hole by hand, wait a few minutes, then slice off any excess with a trowel. If you have a leaky spot in a foundation wall, swimming pool, garden pond or fountain, hydraulic cement is the repair product for the job.

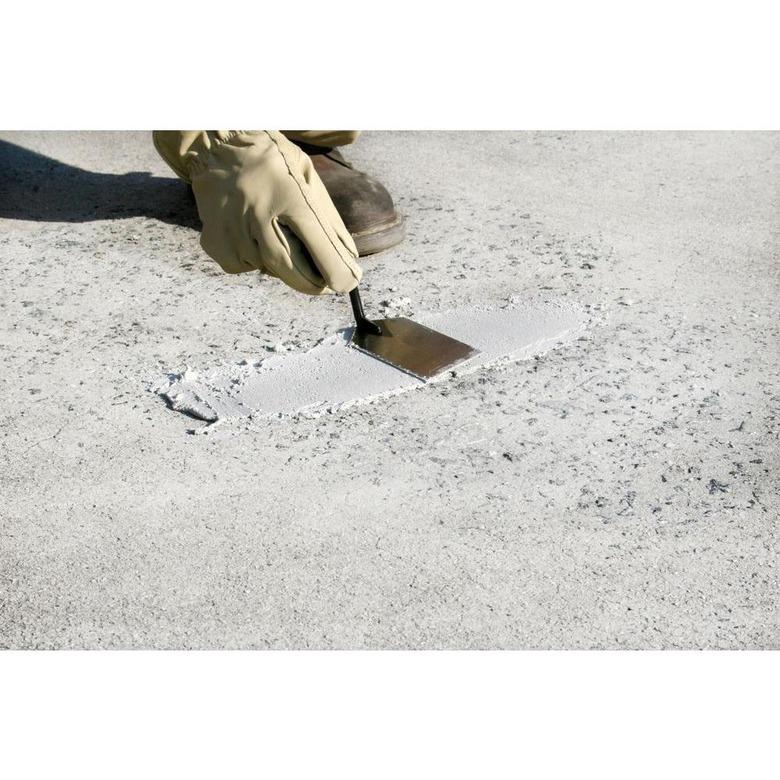

5. Patching Compound

Concrete patching compound comes in a variety of formulas but typically consists of cement mixed with vinyl or other polymer resins for workability and bonding strength. In general, patching compounds are designed for shallow pits and holes up to 1/4 inch deep and covering relatively small areas. Compounds come in premixed tubs and in dry powder forms that you mix with water. They are applied with a trowel and can be smoothed to a thin edge to "feather" the patch into the surrounding area.

6. Concrete Resurfacer

Concrete resurfacer is a thin cement-based liquid that you pour out and spread with a squeegee, trowel or brush to create an entirely new layer over damaged concrete slabs. It is made with cement, sand and polymer modifiers and can be applied in thicknesses of 1/16 inch to 3/8 inch. Concrete resurfacer is suitable for indoor and outdoor applications, so you can use it to restore ugly driveways and walks, garage or basement floors or exposed concrete floors in living spaces.

Concrete resurfacer is sold as a dry powder that you mix with water. It is self-leveling and can be allowed to set after it is spread, with no additional tooling; or it can be brushed with a broom for a non-slip finish (recommended for driveways and walkways).

7. Sand Mix Concrete

While resurfacer creates a thin veneer over concrete, sand mix concrete is more like a rebuilder, or a heavy-duty resurfacer, and is ideal for creating a new layer of concrete up to 2 inches thick over existing concrete slabs. Sand mix is a form of concrete, but unlike standard concrete, sand mix has no gravel aggregate so it can be applied in a relatively thin layer. In addition to repair work, sand mix is often used to make concrete countertops or is poured into molds for cast concrete projects.

Making repairs with sand mix concrete involves building a wood form around the repair area, filling the form with wet concrete, then finishing the surface with floats and trowels, as with standard concrete. As with resurfacer, a final non-slip broom finish is recommended for walking surfaces or surfaces that will carry vehicles.